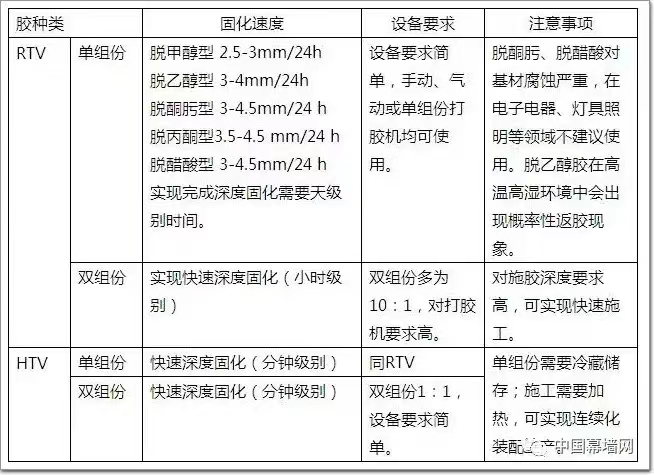

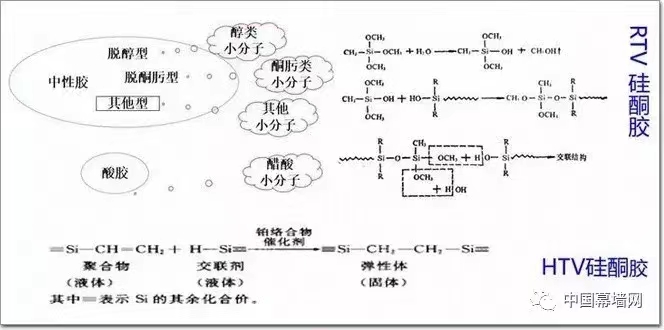

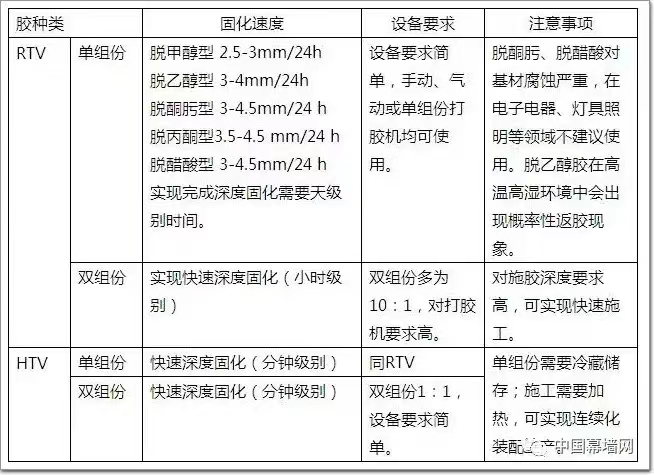

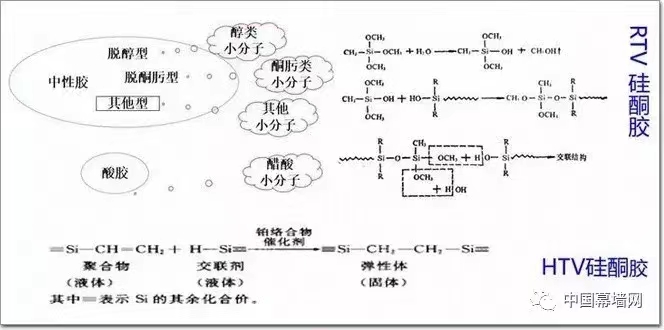

Silicone Sealant is a paste sealing material made of polydimethylsiloxane as the main raw material, supplemented by crosslinking agent, coupling agent and reinforcing filler calcium carbonate or white carbon black, which is placed at room temperature or heated to form silicone rubber elastomer. Because of its excellent heat resistance, cold resistance, weather resistance, excellent electrical properties and a wide range of bonding properties, it is widely used in construction, rail transit, electronic appliances, lighting, switching power supply and other fields, play a key role in waterproof sealing, bonding fixing and device protection. In the actual engineering application and sizing process, construction personnel will find that there are certain differences in the curing speed of silicone sealant in different specific situations. For single component silicone rubber, this difference becomes more and more obvious with the change of seasons, in the upcoming season from autumn to winter, here and each user on the main factors affecting the curing speed of silicone sealant to share. First, the type of sealant impact The type and packaging form of sealant is the key factor affecting the curing speed of silicone sealant, according to the curing mechanism of silicone sealant can be divided into HTV(molding high temperature curing silicone sealant) and RTV(room temperature vulcanized silicone sealant); According to the types of small molecules, RTV can be divided into demethanol, deethanol, deketoxime, deacetone and deacetic acid, etc. (Figure 1. Curing mechanism diagram). HTV packaging form is mainly two-component packaging, a small number of single-component packaging used in the market needs refrigeration storage; RTV packaging form in single-component and two-component coexist, of which single-component construction is simple, low requirements for equipment, in the practical application of the dominant. The type and packaging form of sealant are the key factors affecting the curing speed of silicone sealant; Table 1 lists the curing speed and other precautions of different types and different packaging forms of silicone sealant under standard conditions (temperature 23±2℃, relative humidity 50±5%). Table 1. Curing speed of different kinds of silicone sealant

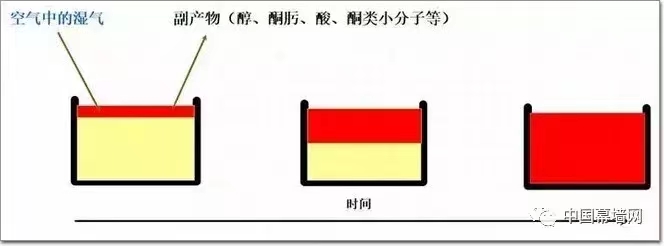

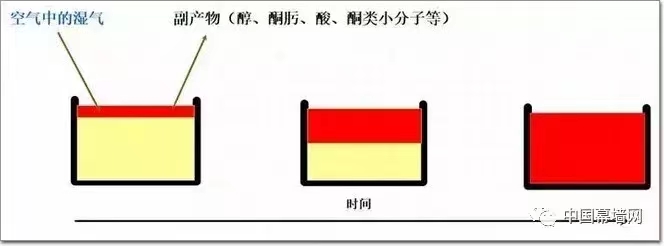

Figure 1. Curing mechanism diagram of silicone sealant Second, the influence of temperature and humidity In the standard conditions (temperature 23±2℃, relative humidity 50±5%), it takes 21 days for the specimen to be cured for a single component and 14 days for a two-component to test the sealant performance data more accurately. For the same RTV silicone sealant, the temperature is the key factor affecting the curing speed. In the environment with moderate humidity, increasing the ambient temperature is beneficial to accelerate the curing of silicone sealant. In areas with four distinct seasons, outdoor sizing or non-constant temperature and humidity environmental conditions often have inconsistent curing speed, and the winter temperature is low, so in winter outdoor construction (or indoor non-constant temperature and humidity conditions), it is necessary to give silicone sealant enough curing time. The curing process of single component silicone sealant is gradually cured from the outside to the inside, while releasing small by-product molecules. As the curing time is delayed, the curing depth increases (Figure 2). Humidity is another important factor affecting single-component RTV, too low or too high humidity will have a significant impact on the deep curing of the sealant, cold winter air humidity is low is another reason for the slow curing speed of silicone sealant. At the same time, the humidity in the air is seriously high (such as the weather along the coast to the south, the water vapor in the air forms a supersaturated state), and the water molecules will form a hydrogen bond network on the surface of the sealant, preventing other water molecules from entering the silicone rubber to participate in the reaction, and ultimately resulting in a slow curing speed of the silicone sealant. For the additive sealant and RTV two-component silicone sealant, increasing the temperature within the appropriate range has a significant effect on the curing speed of the sealant. Relative to the dependence of single-component RTV silicone sealant on external moisture (it is recommended that the single-component gluing depth design should not exceed 1cm), the external humidity has no significant impact on the curing speed of the two. For applications with deep sealing depth and fast deep curing speed, RTV two-component silicone sealant or HTV silicone sealant is recommended.

Figure 1. Curing mechanism diagram of silicone sealant Second, the influence of temperature and humidity In the standard conditions (temperature 23±2℃, relative humidity 50±5%), it takes 21 days for the specimen to be cured for a single component and 14 days for a two-component to test the sealant performance data more accurately. For the same RTV silicone sealant, the temperature is the key factor affecting the curing speed. In the environment with moderate humidity, increasing the ambient temperature is beneficial to accelerate the curing of silicone sealant. In areas with four distinct seasons, outdoor sizing or non-constant temperature and humidity environmental conditions often have inconsistent curing speed, and the winter temperature is low, so in winter outdoor construction (or indoor non-constant temperature and humidity conditions), it is necessary to give silicone sealant enough curing time. The curing process of single component silicone sealant is gradually cured from the outside to the inside, while releasing small by-product molecules. As the curing time is delayed, the curing depth increases (Figure 2). Humidity is another important factor affecting single-component RTV, too low or too high humidity will have a significant impact on the deep curing of the sealant, cold winter air humidity is low is another reason for the slow curing speed of silicone sealant. At the same time, the humidity in the air is seriously high (such as the weather along the coast to the south, the water vapor in the air forms a supersaturated state), and the water molecules will form a hydrogen bond network on the surface of the sealant, preventing other water molecules from entering the silicone rubber to participate in the reaction, and ultimately resulting in a slow curing speed of the silicone sealant. For the additive sealant and RTV two-component silicone sealant, increasing the temperature within the appropriate range has a significant effect on the curing speed of the sealant. Relative to the dependence of single-component RTV silicone sealant on external moisture (it is recommended that the single-component gluing depth design should not exceed 1cm), the external humidity has no significant impact on the curing speed of the two. For applications with deep sealing depth and fast deep curing speed, RTV two-component silicone sealant or HTV silicone sealant is recommended.  Figure 2. Simulation diagram of curing process of single component silicone sealant

Figure 2. Simulation diagram of curing process of single component silicone sealant In addition to the above main factors, in the actual application environment, whether it is the addition of HTV silicone glue, or condensed RTV silicone glue will encounter other probability factors that cause the sealant to cure slowly or not, such as: Molded silicone sealant encounters special environments (heavy metals, PVC, polysulfide polysulfone, phosphorus and nitrogen, etc.) will cause catalyst poisoning and cure abnormal, condensed silicone sealant due to storage failure (storage environment is harsh or too long) resulting in abnormal curing. Therefore, when using sealant, the builder should follow the construction guidelines and sizing precautions provided by the sealant manufacturer as far as possible to carry out construction operations to ensure the normal curing of silicone sealant. As a leading solution provider in the sealant industry, Baiyun Chemical has been committed to helping customers use good glue and provide users with safe and reliable gluing solutions.

We are from China rubber industry Tongchuang.

We specialize in the production of Neutral Silicone Sealant, Acid Silicone Sealant, Structural Sealant, silicone sealant, silicone sealant. We can produce sealants with warranties ranging from 1 to 25 years and pack them according to your requirements.

I hope we can cooperate happily in the near future. If you have any questions, please don't hesitate to contact me.